Products

- Sintered NdFeB magnet

- Bonded NdFeB magnet

- Samarium Cobalt magnet

- Ferrite Magnet

- AlNiCo Magnet

- Custom magnet

- Precision Magnet

Contact Us

- TEL:021-33527763 EXT 602

- Fax:021-33527762

- Email:sales@y-magnet.com

- shengli@y-magnet.com

Samarium Cobalt magnet

Sintered Samarium Cobalt (SmCo) magnets fall into two groups of chemical composition: SmCo5 and Sm2Co17. Armstrong Magnetics accepts orders for custom Samarium Cobalt magnets as per customer design

Samarium Cobalt magnets offer super combination of

extremely high magnetic standard, excellent thermal stability and distinguished corrosion resistance. Sm2Co17 is better than SmCo5 in all respects. Because of these merits, Samarium Cobalt magnets are ideal component specially in applications where temperature changes across a broad range or environment is corrosive, such as chemical pump couplings.

Samarium Cobalt magnets are extremely powerful

The (BH)max of Sm2Co17 is up to 30 MGOe and its Br up to11,000 Gauss.

Samarium Cobalt magnets have very high resistance to demagnetization

Maximum Hci of Samarium Cobalt magnets are as high as 25 KOe.

Samarium Cobalt magnets are suitable for heat applications

Reversible temperature coefficient is -.03 ~ -.0435 of Br/°C. Maximum working temperature is 250 ~ 300°C, under which Samarium Cobalt magnets maintain good magnetic property to temperature changing.

Samarium Cobalt magnets have outstanding resistance to corrosion

There is no need of surface treatment to Samarium Cobalt magnets even if they will work in humid environments.

Samarium Cobalt magnets are hard and brittle

Samarium Cobalt magnets offer super combination of

extremely high magnetic standard, excellent thermal stability and distinguished corrosion resistance. Sm2Co17 is better than SmCo5 in all respects. Because of these merits, Samarium Cobalt magnets are ideal component specially in applications where temperature changes across a broad range or environment is corrosive, such as chemical pump couplings.

Samarium Cobalt magnets are extremely powerful

The (BH)max of Sm2Co17 is up to 30 MGOe and its Br up to11,000 Gauss.

Samarium Cobalt magnets have very high resistance to demagnetization

Maximum Hci of Samarium Cobalt magnets are as high as 25 KOe.

Samarium Cobalt magnets are suitable for heat applications

Reversible temperature coefficient is -.03 ~ -.0435 of Br/°C. Maximum working temperature is 250 ~ 300°C, under which Samarium Cobalt magnets maintain good magnetic property to temperature changing.

Samarium Cobalt magnets have outstanding resistance to corrosion

There is no need of surface treatment to Samarium Cobalt magnets even if they will work in humid environments.

Samarium Cobalt magnets are hard and brittle

It is not possible to machine Samarium Cobalt magnets with conventional machining. Samarium Cobalt magnets can be abrasively machined with coolant served to absorb heating and dust. Without coolant, rare earth magnets could crack and chip by the heat produced during high speed cutting or grinding, and the sparks contain the easily oxidized grinding dust that could cause fire!

Samarium Cobalt Properties

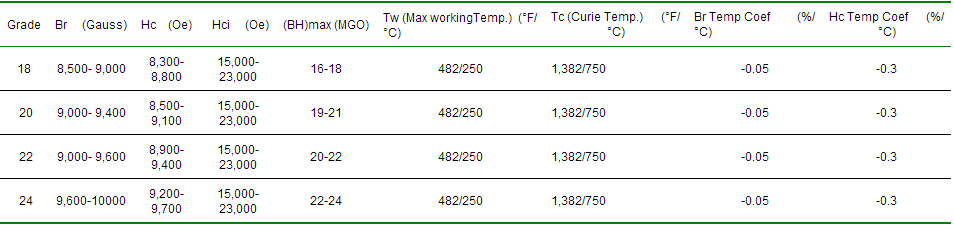

1. SmCo5 materials:

2. Sm2Co17 materials:

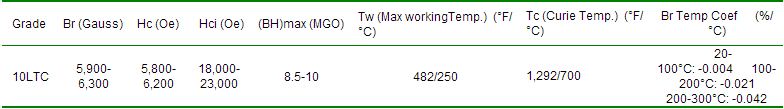

3. SmCo5 materials with Low Temperature Coefficient:

4. Sm2Co17 materials with Low Temperature Coefficient:

4. Sm2Co17 materials with Low Temperature Coefficient:

0086-021-33527762

0086-021-33527762 sales@y-magnet.com

sales@y-magnet.com doyemagnet

doyemagnet Add: No.655,Jiujing Rd,Songjiang

Add: No.655,Jiujing Rd,Songjiang